2 Stroke Fuel Injection

Here's the REAL story on the development of Transfer Port Injection (TPI) by Neil Hintz

Regarding the Origin of TPI (Downloadable PDF)

Regarding the origin of TPI

It all started with the need for more power, I needed to win VMX and my route to the winners circle was more power, or so I thought, if some is good more must be better!

I started out with a 1974 DT360, with the usual hot ups, it went well but not enough. So I played around with alcohol fuel to help keep the ever present detonation at bay and after a time realised this fuel was not well suited to the reed induction twostroke, with fiber reeds not even lasting one meeting

without softening and buggering up the tuning.

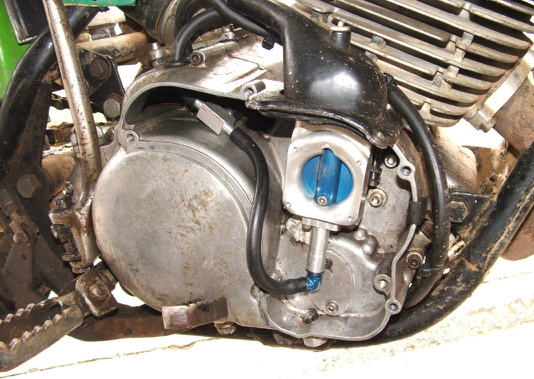

To fix this situation I located a 1973 F9 Kawasaki rotary valve engine, steel valve so no issues with consuming alcohol in this engine. I wanted to run E85 as its readily available at the local fuel pump. I tried to run ethanol through a carburetor first with home made jets and needles with

at best mixed results. Abandoned that idea early on as I was also unhappy about the size of the carburetor sticking out the side as it is with rotary valve engines.

Next came the Lake Injector, not really an injector but more of a controlled leak ( and even then I'm not sure I should use the word “ controlled “ ) straight out of the fuel tank, through a needle jet and straight in under the throttle slide.

No float bowl, no floats, no main jet, nothing.

Turn the fuel tap on and start kicking furiously before you flood the thing. I tried hard to get this Lake Injector to work as it was in keeping with the “spirit of the era” once again mixed results, mostly bad but one meeting the planets must have been aligned as it was a beast, ran flawless with it winning everything we entered. Next meeting it was back to a bag of unmanageable shit, again.

Lake Injector, Google it.

So I needed a more controlled injection system, you know, something along the lines of automotive electronic injection, I'd had a fair bit to do with the NZ made Link ECU fitted to Subaru engines used in aviation, I trusted it, how hard could it be? BUT was it legal for my VMX class, I'd assume not.

On enquiry with the organisers I was told, quote,” you can do anything to your engine but it must look period externally” and then there was this annoying second sentence “ you know, so long as the hot up was done back in the day” bugger.

Two things came to mind, hide it (easier on a rotary valve engine with the induction hiding behind an aluminium cover) and the second was do some research into when the first electronically injected twostroke might have been.

Hiding the my illicit injection system turned out very easy and by pure fluke was the way forward with electronic twostroke injection, I just didn't know it yet.

On the Kawasaki rotary valve engines there is an air induction cavity behind the cylinder, perfect place to secure two bosch injectors discharging into the crankcase toward the catchment of the main transfers. These old Kawasakis had plenty of pipes leading down to the carburetor so no problem hiding TPS and injector wires in some of them. It was also rather lucky in that I was probably the only one in the entire VMX movement that knew anything about these old girls, so if things were not super accurate, I was the only one in the know.

Out of interest It seems the French Motobecane motorcycle manufacturer made an electronically injected twostroke triple back in 1974, (I was running in the pre 1975 class) apparently not very successful but nevertheless a real thing. I photocopied all the information I could about this 350 and kept it in my truck so if a disagreement broke out at the track, this was my last ditch shield.

I thought I knew a bit about fuel injection, how wrong I was, I did a lot of tuning away from prying eyes by way of trail rides. I lost track of the amount of times I had to walk out of the forest and get the sweep team to recover the Kawasaki.

I'm sure I was nearly at the point where they were sick of me at every event, I certainly did some miles on foot and yes got a few odd looks. Several problems, one was (and this had be buggered for a while) every time I started the bike up it would run different, sometimes go like a cut cat, others like a sick slug, what the hell was causing this ?

With our Subaru engines I would always run the injectors batch fire, all together every 180 degrees of crank rotation fuel could not go anywhere else just wait in the manifold for the next induction event. So the Kawasaki being a one cylinder I thought this batch fire would be fine. Turns out the Link ECU would select a spot to inject on batch fire, not necessarily the same spot every time the engine was fired up.

So even with only one cylinder you need sequential firing to have control over the injectors timing.

At last some control and with this came the realisation that injector timing was important, I thought as long as the right amount of fuel was deposited into the crankcase, like the Subaru manifold, that was the end of the matter, I was wrong again. I needed an oscilloscope to see what was happening but that was out of my league, perhaps I thought I might use a timing light? I had an old home brewed 12V battery powered CDI so I hooked up another coil to the ECU injector output with the same voltage and impedance as the injector coils, strapped my CDI trigger coil to this extra coil, set the CDI running with its own spark plug and high tension coil, clipped the timing light to this spare spark plug lead. Every time the injectors fired I got a CDI spark which in turn triggered the timing light, instant "injection on time vision” and by reversing the polarity I could view the injection off point.

Now things became interesting, by shifting the injector “on” timing I could change the way the engine ran, not touching ignition timing or fueling. The closer the injection on point came to the transfer event the better the engine ran, 180 degrees out and it would run real bad, particularly in the lower rpm, off idle and up to before the pipe started to work. It became apparent to me that the pulsed injection deposited a small (short injector duration) pocket of fuel into the crankcase.

This pocket of fuel needed to be deposited at such a time and place that it would all be taken up the transfers every cycle with none left behind to contaminate the the next charge. The best way for this to happen was to have the injectors fire close to the time of transfer. This factor would change the engine from a mouse to a monster on its own.

Fixed, or so I thought-- next came this rather annoying lean condition part way into a ride, approx ten minutes in or so, this also had me scratching my head for a while, in fact I nearly abandoned the whole project at this point and it turns out it was a problem I should have recognised earlier. The rectifier regulator was under the seat snuggled up in foam, it had fins on it, I wonder why? The regulator would overheat and stop charging, the system would drop below 9V, under this voltage the Link ECU could not compensate, so the fuel dosage would drop off, instant lean condition, the regulator would cool then come back on line,again. Caught it one night running it with the voltmeter on it. New regulator fitted but this time mounted under the engine, cooled by air, water, sand and rocks now, no more voltage / lean running problems.

Nearly there, now I could run a whole ride without the engine jumping in and out of tune but still there was a problem. Running E85, there seems to be a temperature point where you need to up the fueling. I have a temp sensor carefully placed out of obvious sight on the Kawasakis cylinder head. It seemed to me that when the sensor read anything over 70 degrees C you needed to add master fuel (all fuel to the system) by about 5 to 7 % thankfully the Link ECU has a graph especially for this situation. At 70C I upped the fuel rate and again at about 120C I started ramping the fueling way up, detonation protection on the old air cooled engine. Nice to have an ECU on board. The old girl has done nearly 100 hours now set up like this, I could never win at VMX as it seems skill is also needed, no matter how much power you have. The Kawasaki is mostly just used for Vinduro and trail riding now, a lovely engine with a broad power spread, easy to ride, lots of fun.

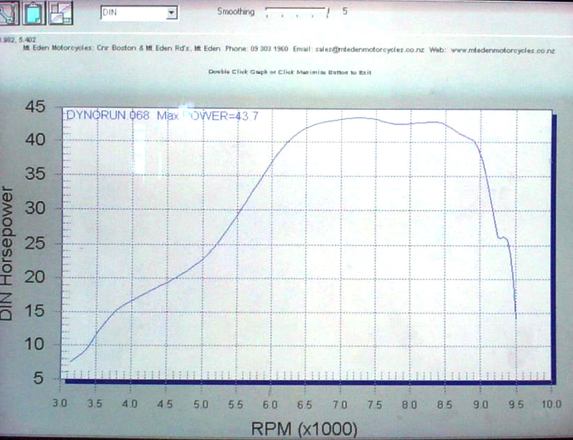

Rear wheel HP dyno graph.

This early twostroke electronic injection experimentation didn't go unnoticed by the local Yamaha dealer, luckily he didn't laugh at me, in fact he had clearly been watching how well the old Kawasaki went on injection and wondered if we might do the same for his YZ250.

This was by now 2012, I had started working on my Kawasaki approx 2008. With some thought and using what I had already learnt we came upon the idea of placing the injectors in the YZ’s B ports pointing down towards the upcoming air charge, with the thought of better air fuel mixing also easier packaging, we wouldn't have to modify the exhaust to go round any injectors if they stuck straight out.

One other benefit we thought was with this positioning we could have a place to store the extra fuel each cycle as the injector on times overcame the B port gas flow time higher up in the revs. But at low speed we were able to let a little air go first then add fuel, this making it near impossible for the fuel component of the charge to make it out the exhaust port before it closed.

Seems we were right. The YZ ran nice (on petrol) right out of the box, Wayne did an hours worth of “seat of the pants tuning” before we entered it in its first ride. It ran so well you could have washed it and sold it out of the showroom Monday morning. We did many rides with his TPI YZ against my standard carburetor YZ. Same day, same riders swapping bikes every circuit, recording fuel burn as we went. The TPI would consistently burn less fuel than the carburetor bike, 14% for the faster tracks and up to 21% on the slower tighter rides, same top end power on the dyno. Wayne and I had this bike up and running in events throughout 2013.

...culminating the Acerbis four hour in November.

Such was its reliability and packaging no one even noticed this rather special bike, in fact it has been run in may more events since then with very few even spotting its injection.

The KTM Connection

And there it would have stayed but for KTM noticing it at about the time they had come up short with their own injection development. An article was presented to Kiwi Rider magazine 2014, written and researched by an ex KTM employee. He did ask if he could send the article and information back to his friend in the twostroke development department of KTM. We had no reason to believe that KTM would even be interested as the ex employee told us KTMs injection was far more sophisticated than ours but there might be some passing interest. Being that in KTMs latest press release they state “ TPI was accidentally discovered in 2014” , I think more than a passing interest, saved their bacon I would say.

The YZ250 TPI development has in turn lead to a new TPI design on a new engine, all packaged in a 250F alloy frame. The new engine is a 360cc rotary valve unit with what I term MK2 TPI also a few other innovations I’ll detail in my next article on the development of the Variable Rotary Housing concept.

Unfortunately I can’t reveal the mk2 TPI system just yet (KTM might be watching again) and I've promised interested parties I won't reveal this system at the moment. I would like to think Im only a few months away from getting some test time on this new bike. The reason for this technology, Variable Rotary Valve Housing and MK2 TPI is to have a no compromise top end engine but still have smooth clean controlled low and mid range, with the ability to not waste raw fuel out the exhaust, with some injector manipulation to help control power and apply real traction control, not just ignition retard as with normal two strokes.

Can't wait.