Navigation Menu

The RG's cases seem to be pretty durable. Plenty of engines have been tuned to 150+ hp and 70+ ft-lbs, with no issues of them simply chronically failing due to weakness. So, that's good.

There are plenty of videos on Youtube etc, pages on FB showing how to take these things apart, so I'll skip that stuff. Be aware that there ARE some nice lugs that you can use when separating the case halves, if you use a bolt and a nut. Please don't hammer a screwdriver into the parting line!

Broken Cases:

Believe it or not, there are a number of places that can fix damaged cases. Since there is no aftermarket for RG cases, save them if you break one and get it fixed if necessary. So.....

http://www.classic-motorcycle-build.com/repair-cracked-cases.html

https://itstillruns.com/repair-cast-aluminum-crankcase-12169859.html

http://www.antiquemotorcycle.org/bboard/showthread.php?21634-Cold-Case-repairs

http://www.allmetalweldingservices.co.uk/MobileOnsiteMotorcycleWeldingRepairs.html

http://focklermachineshop.com/portfolio-view/henderson-motorcycle-engine-repair/

http://www.prcfabrications.com/restoration_timing_cover.html

http://metalcraftracing.com/welding-repair-fabrication-services/

https://www.fdmotorcycles.co.uk/services/

New cases and mismatched sets:

As far as I can gather, engine cases were sold as an upper+ lower, PLUS the trasnmission side plate - a complete, matched set. Some of us have merrily mixed and matched these parts - especially transmission side plates - with no issues. However, experienced engine builders do NOT view these as casually interchangeable parts. So, we probably shouldn't either. Just because "it worked fine for me!" doesn't mean you should bet your engine's health and future on a lucky accident when fitting mismatched parts.

Bearing Crush

A critical dimension is 'bearing crush". Predictably, this is the amount that the bearing hole is smaller than the actual bearing. .001 to .0015" or so. This is achieved by precisely boring the holes in the case >while the cases are assembled and torqued together< There is a reason bearings have a specified tolerance, there is also a reason why you DON'T want to use very tight-toleranced bearings.

Here's an anecdote from an experienced tuner, the mysterious KC:

"The bearing makers advise that if the inner race is a press-fit and especially if there is outer race pre-load, C3 (extra internal clearance) bearings must be specified.

About the only thing I've ever seen stop outer race creep was those orange strips let into recessed areas on the ODs of NTN bearings Kawasaki was using. They took a good "print" of the surface finish and their resilience seemed able to keep them from turning. I've seen quite a few TZ main bearings (which had a tiny protruding ball set into the outer race OD as a locking feature) drag, chatter, and chew their way around. Times I've tried Loctite, it didn't work. I believe Kel had the same experience.

I'm remembering a good ole boy at some race, holding forth about how he decided to treat his TZ to a set of high grade US made mains (back when there was US manufacturing). He proceeded to tell me that he'd put ABEC-7 bearings on his crank so I knew what was coming next. Precision grades are not available in C3, so when he started his engine for the first time after the rebuild its mains seized. His conclusion? "There's somep'n about them Jap bikes that just needs them junk bearings!"

I'd think your estimate of .001 - .0015 is good.

KC"

And from another experienced builder:

"I know that many have said that the case halves can be swapped, but I say "no way" The main bores are too precise in their size requirement to consider exchanging tops/bottoms. If you wanted to try that because of no other choice, then the chosen case halves could be assembled together, and torqued to spec, then measured to compare to the main bearing OD.

The case should be 0.0008, to 0.0018" tighter than the bearings.

With used crank bearings, it might stand to be a bit tighter than that ...maybe 0.0022" or so...but anything tighter is not good.

Now, that being said, I am a guy who has changed many main caps on V-8's to repair or convert to 4 bolt caps. From that experience, I can tell you that it's very unlikely that the cases can fit well enough to fit within that spec when exchanged."

Cleaning and prepping cases

Methods vary!

Vapor blasting (as seen below) appears to be an extremely effective process, leaving a very nice-looking result.

Soda blasting (I did this last time) uses a water-soluble media which should be easy to clean/rinse from every nook and cranny. Soda blasting is NOT terribly aggressive - which is good, if that's what you want- but it won't leave a bare naked finish like vapor blasting.

Ultrasonic cleaning if you can find a place with an industrial tank big enough - is fantastic. I use it for all my small parts.

The Good Old Car Wash Man there is nothing like high pressure car wash.

Just be careful if you try to hold anything with your hand, as the high pressure stream will lay you open like a fillet knife. And, it's dirty water, so you'll get the infection from hell.

Bead blasting I would be very cautious here. I would use this only on exterior surfaces, and make sure every bolt hole has a bolt or plug stuck into it. I did bead blast a set of cases, and the micro abrasive silica particles can become embedded in the surface of the part. Worse, this can happen if you let the beads shoot down a threaded hole. Then, you get bolts that squeak and groan and bind as you tighten them, even if you then laboriously chase every hole with a tap. So don't do this. Just... be careful when bead blasting.

Dishwasher: Be aware that the soap in the dishwasher can be causting and attack your aluminum. Do your homework and find a soap that is not harmful to aluminum.

Oh, wait, here's a great compilation. And, now that I'm getting smarter, I have saved it as a PDF. If that site ever closes, I'll post the info directly.

http://www.team.net/sol/tech/clean_al.html

Below are pics of an incredibly clean engine, I assume after vapor blasting:

Engine case trivia RG500

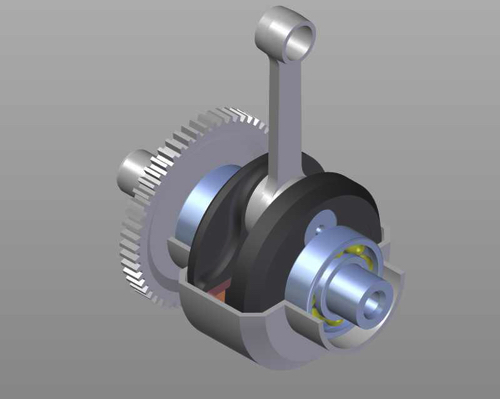

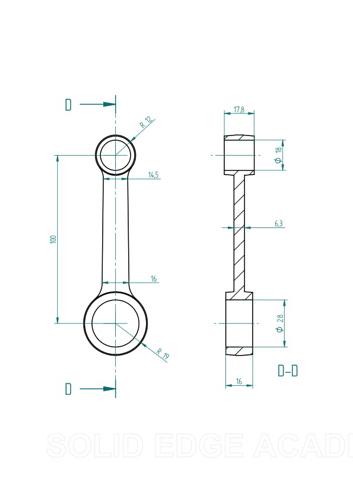

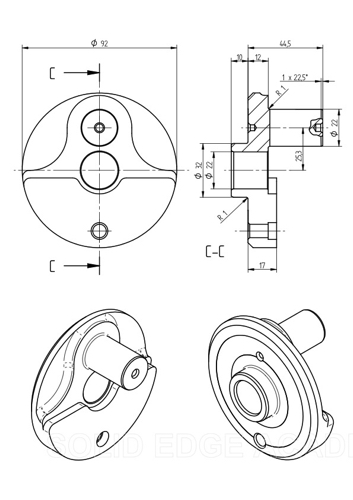

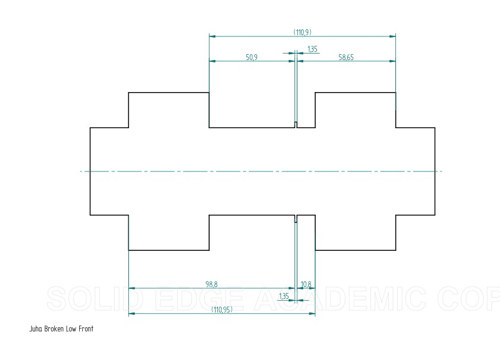

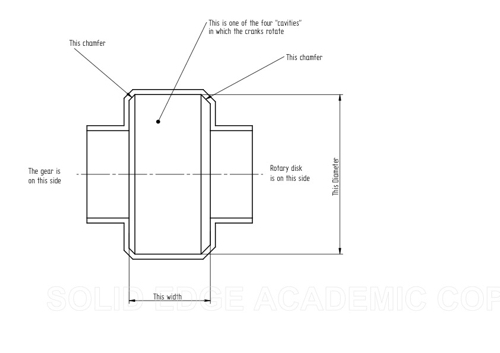

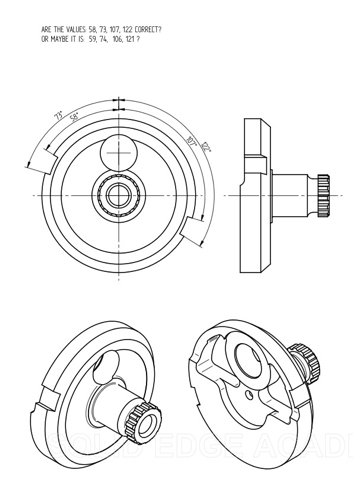

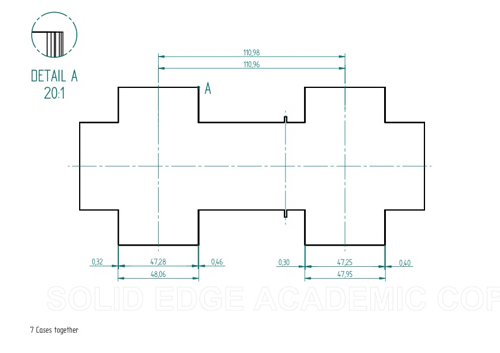

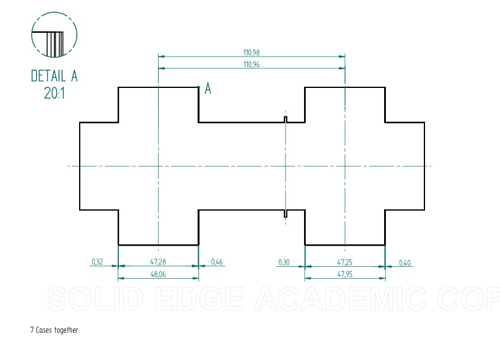

Some CAD drawings:

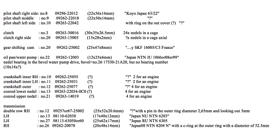

Bearing Sizes for RG:

click to enlarge

Bearing Sizes for RG:

Case Volume and Case Compression Ratio

Case Volume is about 390cc's at BDC in the 500 Gamma.

With the 10mm longer rod installed in the Delta, the volume will go up 43cc's + whatever the larger transfer ports give. This will change the crankcase compression ratio from 1.33 to 1.29 or less. Most modern reed dirt bikes and snowmobiles are in this area.

AS MEASURED:delta

TDC 559 ml

BDC 434 ml

559/434= 1.288:1

A little snippet from KC:

"With exhaust pipes at an ineffective 1950s level of development, the only

way to move mixture up thru the transfers was with high case compression, to ridiculous numbers like 1.5:1 , 1.6: 1, or even 1.7: 1 This moved the

charge, but as a result it moved at such high speed that it short circuited to

the exhaust port in very little time. The result of this high speed jet is a

very narrow powerband. With then-fashionable high CCR, larger transfers didnt work, the case charge blew out too fast and got lost out the exhaust.

(After more transfer experiments) in time, those silly high CCRs were given up in favor of a still-high 1.5: 1, this was in the 1965- 1970 period....why did a bigger case work better? You could suck more out of it, exhaust pipe design advanced and the pipe began to take over a large part of the transfer pumping work from the case. The case is a sealed room from which the engine has to breathe. The bigger the room, the deeper the breathing....

Case volume continued to increase, dropping from 1.5:1 down to 1.35:1 by the early 1970s. At that time, stuffing the case showed we were losing revs off the bottom and gaining absolutely nothing on top."

Just for fun, here's SAE 670030, a paper exploring crankcase volume and its effect on charge delivery ratios: SAE_670030

Want to run Ceramic bearings? Here's info on Ceramic Hybrid Bearings

Adapting RG400 cases to take 500 barrels? enlarge bores on case from 60 mm to 66.0 mm

After you put together an engine, do you pressure and vacuum test for leaks? Here's how: http://www.macdizzy.com/leakdown.htm