Navigation Menu

Port timings, tracings, and tweakings

How tall is a stock cylinder?

3.427" all 4 corners, or 87.0mm

One time I sent my cylinders out for work, and when they came back, one was shorter than the other three. 8-/

Why the different front and rear base gaskets?

One of the gaskets has a reduced hole.

It's the one that is in "front" of where the water is

arriving from the water pump.

There is dynamic water pressure there, and if the hole was the

same as the others, the cylinder above it would get most of

the water so you would have one cold cylinder and three hot cylinders.

I assume Suzuki made a lot of experiments with different hole

diameters until it found the size which makes the water evenly

distributed among the four cylinders...

so the bottom line is: DO NOT change that hole! :-)

Specs on just some tuned RG: (but a very strong runner)

Exhaust port opens 81.5 ATDC

height 25.86 mm

area 953.66

max width 41.5

Inlet opens 139 BTDC

duration 210 deg

area 780.71

height 25 (no growth potential there, must be on the sides)

width 38.3

swept vol 138.3

trapped stroke 24.7

trapped cr 7.4

geometric cr 14.2

bowl cc 10.5

.385 squish area ratio

Darcy pipes

Tuning up the port chamfers after running:

Chamfer after boring. Take top end off after first days practice sessions

are over, or maybe something like 50 miles on a street bike (just an

educated guess) and look for wear areas (usually shiny looking) on the

piston. Use a fine emery or crocus cloth to gently relieve any wear spots

you find in a cross hatch manner. Inspect rings for snagging areas,

likewise with the port top and bottom edges. Exhaust is the worst offender

because it is so large and shaping is critical. Transfers rarely bother

but still need to be free of sharp edges. Check bottom edge of piston on

intake side for hard contact with the bottom of the intake port, a big

radius on the port bottom is best, although this is not a major concern

with bridged intake port style cylinders.

Also be sure to check ring-end gap. Very critical for long ring life.

Follow piston/ring manufacturers spec.

There's the basics in a nutshell.

Geoff B.

Specs on my 127 HP , 516cc RG with Suzuki cylinders

This motor has TMX35mm carbs, but other than that is not in a remarkable state of tune.

57 x 50.6 B/S, (second overbore)

Exhaust port opens 84 deg ATDC,

Transfers open 119- 122 deg ATDC (staggered)

ports shaped and modified by Eric Gorr

disc timing opens @ 47 mm BTDC (145 deg)

closes @ 20mm ATDC (71 deg)

compression 150 psi cranking

head volume trapped volume 10.0cc to bottom of plug threads, 10.5cc including plug,

piston intrusion= 2.8cc less than flat plate

12.9: 1 mechanical CR

trapped CR 7.07 :1

The darcy pipes are 113mm max width, and use a 23.5mm ID exhaust

stinger at the outlet.

TMX35 carbs on enlarged inlet ports

So really not pushing the limits on anything.

Just a good setup, great porting, and a fantastic set of pipes.

Randy N

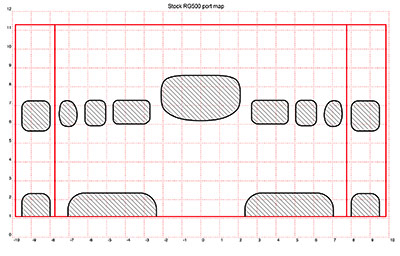

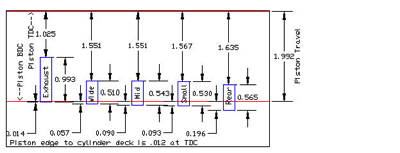

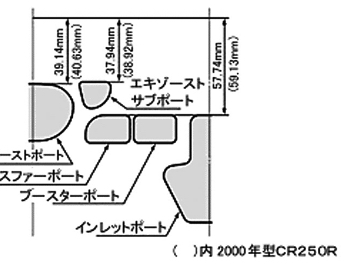

Stock RG port map

RG500 Cylinders part 2

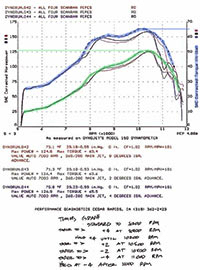

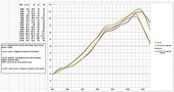

Dyno chart from my RG516

127 HP on Superflow-calib. Dynojet

Compare vs the big bikes run on the same day, same dyno! Within 4 HP of a tuned , '00 YZF-R1

Chart above shows dialing-in ignition advance curves on DJ150 calibrated to match Superflow

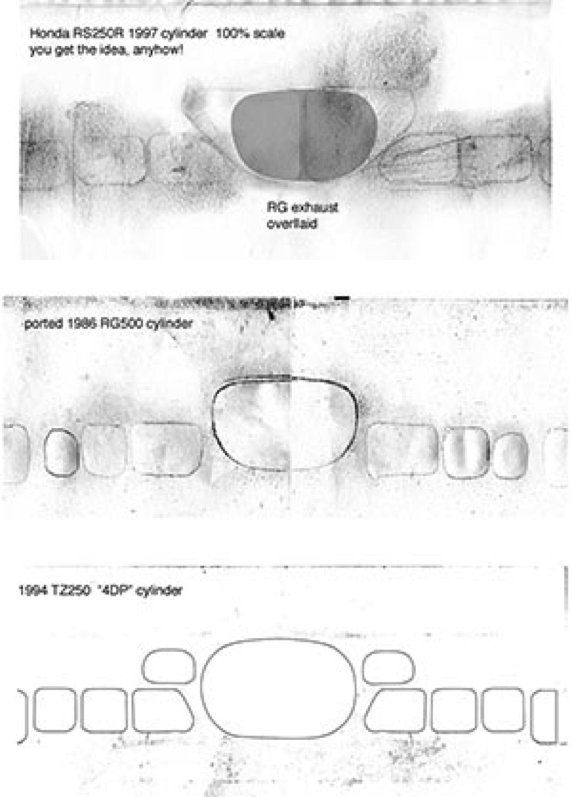

Before you get depressed and think, "Man, those other ports are so huge!" remember that a TZ in race operation gets a new set of pistons and rings every 300 miles. Fortunately for us, the TZ can live at 12500-13000 RPM. When you bring that down to street-level RPM, they last a long time. After 3000 miles, my pistons showed nearly no wear and leakdown was still excellent. I suspect, if it weren't for my tendency to take things apart often, they would last 10,000 miles. The powervalve, however, might get pretty sticky by then. hmm.

The RG cylinders do a great job in the 7500-10500 RPM range, don't be too hasty to change them out wholesale for other parts. Cranks, rods and pistons last a lot longer in a lower-revving motor!

On the other hand, if you must have a lot of power, the 250GP parts are in a different class, obviously. Plus, they are designed to handle pretty much continuous output in the 350 hp/liter range, so when "detuned" in an RG appliction, down to 300 hp/liter, they barely even know they're on the job. This is in contrast to iron-liner RG barrels that I suspect are reaching their reliability limits around 270 hp/liter.

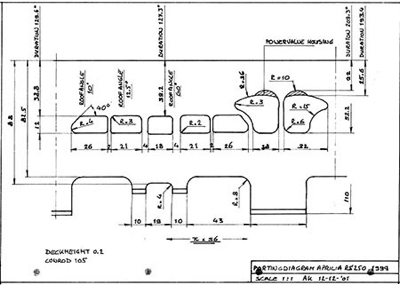

Above is a technical drawing of the ports made by... some dedicated guy. I don't have a credit on this one. click to enlarge.

So, OK, how does this stack up versus a "Real" high-performance cylinder?

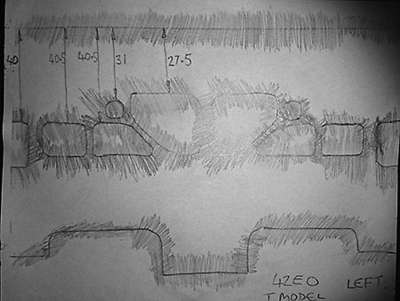

Here's ported RG vs an RS250R (1997) and my TZ250 barrels on the Delta

RG500 port map vs 250GP cylinders click image to enlarge

RG500 port timings by anonymous

Misc port maps

Modifying the port timings

Modifying the exhaust port is straightforward if you have done prior port work. The transfers are not so simple, and easy to mess up. Also, you have to make a correct change to work in synch with your pipe and the rest of the setup. This is one place where you can't easily undo damage - so if you must modify things, find someone who knows what they are doing and pay them to go with a proven setup on your cylinders! If not, it's probably best to leave these things alone. Or... is it?

If you're dying to play with ports, an RG is a hard place to start because you have to do everything FOUR times. So to learn about porting and tuning, start on some other bike! But there are things you can do on an RG's cylinders that can be completely reversed, if you want to change things.

Here's one way:

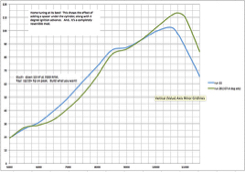

Spacing the cylinder up - advancing port timings- Dyno test

Have you guys seen this one? Simply install a spacer underneath the cylinders, and raise ALL the ports a little bit- no need to take a grinder to your precious cylinders. Then use a thinner head gasket to regain some of the lost compression - and there you are! Instant porting job.

Thanks to the miracle of the Gammalist, a discussion occurred where we came up with a plan do do exactly this. Richard Kosar had the ability to cut a spacer from a peel-ply metal laminate of some sort, which could be peeled to desired thickness. Each layer was like a sheet of tin foil.

I installed these on my engine and went off to the dyno - here's the subsequent report on Gammalist:

3D render of spacer plates

Report after the dyno test weekend:

Date: 97-07-27

This is probably going to be lengthy, so bail out now if you wish!

Based on Mota simulation predictions by James Hunt, I was looking for a 5-6

hp boost by raising the barrels on the RG. so I added a 0.035" spacer under

the cylinders, used a thinner headgasket, did a tiny bit of porting, and

headed off to the dyno.

net result was

1) cylinders and all ports raised by 0.035"

2) reduced head gasket thickness by apx 0.020" to compensate

3) squish clearance increased by approx 0.015", to approx 0.045".

4) compression at kickover reduced from 150 psi (before spacers) to 133 psi

w/ spacers.

I have run hi and low compression setups before, and figured this would best

compare to my low compression (130 psi head) runs. that would be run #11. I

now have 28 runs on the Gamma! today were runs 26-28.

compression vs timing requirements recap:

I have found, over and over again, that a high compression setup (high enough

to where I would worry about deto if I went much further, in this case 150

psi cranking) does not make any more power if you advance the timing beyond

stock. it may fill in the upper-midrange, but generally clips a little off

the peak numbers, and kills overrev.

I have also found that on the low comp setup, advancing the timing beyond

stock boosted power from the midrange on up, w no penalty.

---<;>short story: I got 113.3 rear wheel hp today, from a low compression

motor that is worse in nearly every way than my old, lower-revving but much

torquier setup. I am very certain I could get 115+ hp tomorrow, if I wished,

by raising compression back to 150 psi and keeping this setup.

made 3 runs today. run 26 was to feel things out. run 27 I leaned it out 1

jet size. run 28 I advanced the timing 4 degrees. I'll plot runs 27 and 28,

vs the "baseline" in this case, runs 11 ad 12, same cylinders but no base

spacers, and using stock heads which had apx 0.060 squish and 130 psi

cranking. so it was a pretty similar setup as far as squish & compression,

mostly just changed the port timings. additional but unknown changes were

smoothing the top of the exhaust port a little, and widening the exhaust port

1mm total to 40.5mm. I feel that streamlining the port and increasing port

area incrimentally would not cause the drop in midrange I saw today. I feel

the results reflect the change in port heights, but I can't make 100 trips to

the dyno, so sue me if I'm making an educated guess and skip a few steps!

more info: in the first LC vs HC test, the 130 psi setup was 6.6 peak hp

below the 150 psi setup. advancing the timing 4 degrees on the LC setup

gained me 4.7 hp on top.

today, advancing the timing 4 degrees on a 133 psi setup gained me 4.3 hp on

top. This setup responded very much like the previous LC setup. I am pretty

certain another ~2 hp can be had by raising compression to prior levels.

run 11 = baseline motor, but w/ stock heads. comp 130 psi, squish ~ 0.060".

run 12 = same + 4 degrees of advance at the pickup

run 27= baseline, + exh widened 1mm, port smoothed slightly, cylinders raised

0.035", comp 133 psi, stock advance curve

run 28 = same as prev + 4 degrees of advance at the pickup

all runs made using the "scan-ran-O-matic Induction System, TM, pat pending."

only got curves today, no breakdown by RPM increments, so once again I'm

'guesstimating' numbers from the graph (for 27 and 28) and not reading

directly from a table, except for the peak number.

run # 11 12 27 28

5000 19.2 18.9 na na

5500 26 23.7 27 27

6000 31 30.5 29 29

6500 39.5 38.8 33 33

7000 49.5 48.5 41.5 41.5

7500 61.6 61.1 51 52

8000 73.1 73.6 66 66

8500 85.2 88.0 80 82

9000 87.2 90.3 83 86

9500 92.9 96.3 90 93

10 K 99.3 103.2 95 102

10.5K 102.4 107.3 107 111

10.75 97.5 99.5 109 113.3

11K 87.5 87.1 108 110

11.5K 65.5 62.5 94 84

So this was a great mod, as long as you ride between 9500 and 11500 rpm.

(There really is a massive gain with the spacers and timing bump in this range - say, great for drag racing, or teaching your buddy's GSXR a lesson.)

I rode this motor at the track last weekend, and it felt, well, flat in the

middle and peaky on top. My old mega-torque setup would definitely

get off corners harder and probably lap faster and easier as well. Yes, it

really is pretty quick now, if you keep it screaming, but the loss in power

below that is pretty noticeable.

FWIW the Mota simulation was very close, I did in fact pick up the predicted

6 hp. Mota says 5-6 more by moving the carbs in and similar gain w/ the new

pipe. So far, I'm a believer! I may test the carb business temporarily on 3

of the 4 carbs. Any ideas on how to make a TMX 1/2 inch shorter in the float

bowl???

PS: Thanks again to everyone lending technical, idealogical, and material

assistance: Richard Kosar, Jim Comrie, "Rustie!!!!!!!????", James Hunt, Darcy

Rosentreter, Greg lewis, Rob Murray, 'Our Lurking Guru' KC, Non-lurking Guru

Dale Alexander, and as always Rob Creighton at Performance Diagnostics in

Springville, Iowa.

click image for all data from this test

Dyno plot of before-and-after runs.

Run 11 vs Run 28